How Do Buyers Compare Wholesale Costs for 7kW vs. 22kW Smart AC EV Chargers?

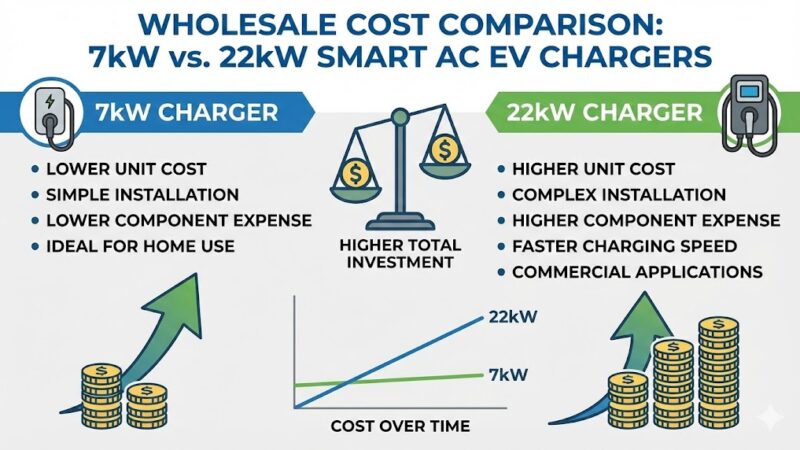

For procurement managers, distributors, installers, and OEM project buyers, choosing between 7kW and 22kW Smart AC EV Chargers is not just a technical decision—it is a financial and strategic one. These two charger categories serve similar markets, yet their wholesale cost structures differ in ways that affect pricing strategy, project profitability, logistics handling, and even long-term customer satisfaction.

Smart buyers never compare chargers simply by “price per unit.”

They compare by value, specification, market fit, installation scenario, component cost, regulatory requirements, and future maintenance expectations. A 7kW charger may be cheaper upfront, but may not fit a high-demand environment. A 22kW charger may offer better ROI in certain regions but require higher installation costs.

This article explores how buyers compare wholesale costs for 7kW vs. 22kW Smart AC EV Chargers, combining engineering knowledge, procurement logic, and real-world wholesale insights.

Table of Contents

1. Understanding the Fundamental Difference Between 7kW and 22kW AC Chargers

Before discussing cost, buyers need clarity about how these two charger types differ in practical use.

1.1 Power Level Defines Charging Speed

7kW = Single-phase, 230V, approx. 32A

22kW = Three-phase, 400V, approx. 32A (11kW is 16A per phase)

22kW is roughly 3× faster—but only if the vehicle supports three-phase AC.

1.2 Market Fit Varies

7kW chargers are ideal for:

Residential homes

Small businesses

Overnight charging

Countries with mostly single-phase grids (UK, many EU households)

22kW chargers are ideal for:

Commercial parking facilities

Fleets

Workplaces

Hotels and shared apartments

Regions with strong three-phase availability (Germany, Netherlands, Norway)

1.3 Different User Expectations

Buyers evaluate cost differences with customer usage patterns in mind:

Residential users prioritize price, safety, reliability

Commercial users prioritize speed, uptime, and ROI

This shapes cost comparison logic.

2. Different Hardware Requirements Directly Influence Wholesale Prices

The most obvious cost differences come from hardware.

2.1 Power Hardware Is More Expensive in 22kW Models

22kW chargers require:

Three-phase relay/contactor

Higher power-rated components

Larger heat sinks

Heavier internal wiring

More robust terminals

These significantly increase manufacturing cost.

2.2 PCB Structure Is More Complex for 22kW

A 7kW PCB is typically:

Single-phase architecture

Simpler power routing

Fewer thermal hotspots

A 22kW PCB requires:

Three-phase balancing

Larger copper layers

Enhanced insulation spacing

Additional sensors

Stronger surge protection

PCB complexity alone can raise the cost by 25–40%.

2.3 Cable Cost Shows a Major Difference

Type 2 cables for 22kW require:

Thicker copper

Larger gauge

Higher heat resistance

Cable price differences are dramatic:

7kW cable is usually 3-core

22kW cable is 5-core with thicker wires

Buyers know cable cost is often the single largest component cost.

3. Installation Requirements Affect Buyer Cost Strategy

Wholesale buyers always consider installation cost because it influences market demand.

3.1 7kW Installation Is Cheaper

Residential installers prefer 7kW because:

Uses single-phase

Requires simpler breakers

Lower wiring cost

Fewer inspection requirements

This increases the market volume for 7kW, making wholesale buying easier.

3.2 22kW Installation Requires Three-Phase Wiring

Commercial installations require:

Upgraded electrical panels

Larger circuit breakers

Heavier cabling

Professional installation teams

Installation cost influences wholesale demand patterns.

3.3 Buyers Compare Not Just Product Price but Market Penetration Opportunity

A 22kW charger might be more profitable per unit—

but the 7kW charger sells in much higher volume.

4. Component Sourcing Differences Shape Price Gaps

Experienced buyers know that sourcing stability drives cost.

4.1 Relays and Contactors

22kW relays are:

Bigger

More durable

Triple-phase

More expensive

This alone can double cost compared to 7kW.

4.2 CT Sensors and Leakage Detection Modules

Higher current means:

More sensitive CT clamps

More advanced DC leakage detection

Cost escalates accordingly.

4.3 PCB Copper Thickness

22kW chargers often require:

2oz or 3oz copper

Multi-layer PCB construction

Higher copper prices and PCB thickness directly increase BOM cost.

5. Cooling and Thermal Design Impact Manufacturing Price

Heat generated in 22kW charging sessions is significantly higher.

5.1 Heavier Heat Sinks

22kW models need:

Larger heat sinks

Better convection paths

More thermal pads

This increases both material and assembly cost.

5.2 More Complex Enclosure Design

22kW enclosures must handle:

Higher temperature

Larger internal volume

Better airflow

A stronger, thicker enclosure means more expensive molds and higher plastic cost.

6. Firmware Complexity Differs Between 7kW and 22kW Chargers

Smart chargers rely heavily on firmware.

6.1 Three-Phase Load Balancing Is More Complex

22kW firmware includes:

Phase detection

Phase rotation correction

Balancing algorithms

More advanced thermal logic

This increases software development cost and ongoing support cost.

6.2 Commercial Features Are Often Required for 22kW Models

Buyers evaluate whether the charger supports:

OCPP protocols

RFID

Smart metering

Dynamic load balancing

Over-the-air updates

More features = higher firmware investment.

7. Certification Adds Significant Cost Differences

Certification is not optional—it is essential in wholesale markets.

7.1 22kW Chargers Require More Extensive Testing

Three-phase testing includes:

thermal cycling

EMC stress

leakage detection validation

high-load endurance

Testing cost influences wholesale cost significantly.

7.2 More Expensive Components Are Required to Pass Tests

To meet CE, EMC, and safety rules:

higher-spec relays

stronger PCB insulation

improved surge protection

Certification-driven improvements add cost.

8. Packaging and Logistics: The Hidden Cost Every Buyer Evaluates

Professional buyers know that shipping cost affects true wholesale value.

8.1 22kW Chargers Are Heavier

This impacts:

pallet loading

carton durability

freight cost per unit

8.2 Larger Boxes Mean Higher Shipping Fees

22kW chargers need bigger boxes due to:

thicker cables

heavier internal structure

larger mounting accessories

Buyers compare CBM (cubic meters) as part of cost analysis.

8.3 Damage Risk Influences Packaging Investment

22kW chargers require:

double-wall cartons

thicker foam inserts

This improves product protection but increases packaging cost.

9. Demand and Market Strategy Influence Cost Comparisons

Wholesale buyers evaluate market dynamics carefully.

9.1 7kW Sells More Volume

This leads to:

lower shipping cost per unit

more predictable stock turnover

better cash flow

9.2 22kW Offers Higher Margins per Unit

In many markets:

commercial buyers pay more

installers have fixed profit percentages

long-term ROI is higher

9.3 Regional Grid Differences Affect Buyer Strategy

Examples:

Germany and Netherlands: 22kW is common

UK and parts of France: 7kW dominates

Nordic countries: both are strong

Smart buyers choose chargers that match regional adoption.

10. After-Sales Cost Shapes Wholesale Comparison

A charger’s true cost includes support costs.

10.1 22kW Chargers Have Higher Failure Impact

Failures are costly due to:

installation complexity

larger replacement cost

downtime for commercial clients

Wholesale buyers evaluate risk carefully.

10.2 7kW Chargers Have Lower Service Cost

Residential users typically encounter:

simple installation

fewer load issues

easier replacement process

This reduces long-term cost for the buyer.

10.3 Spare Parts and Maintenance Cost Differ

22kW chargers use:

bigger relays

thicker cables

more advanced PCBs

Spare parts cost more accordingly.

11. Human Decision Factors: Buyers Evaluate With Both Logic and Experience

Cost comparison is not just technical—it is emotional and practical.

11.1 Buyers Think About Their Customers

They ask:

“Will my customer pay this price?”

“Can installers support this model easily?”

“What happens if something fails on-site?”

A good buyer considers real-world stress.

11.2 Buyers Think About Stocking Cost

Heavier chargers = more warehouse cost.

Higher-value chargers = more capital tied up.

11.3 Buyers Think About Market Positioning

Some brands want affordability (7kW).

Others want premium performance (22kW).

Buyers choose based on brand identity.

Conclusion: How Smart Buyers Compare Wholesale Costs

Professional buyers compare wholesale costs for 7kW vs. 22kW Smart AC EV Chargers based on:

hardware complexity

component cost

cable and connector differences

installation difficulty

firmware requirements

certification cost

logistics and shipping

after-sales risk

market demand

long-term customer expectations

brand positioning

7kW chargers are more affordable, simpler to install, and ideal for residential volume sales.

22kW chargers offer higher performance, stronger commercial value, and better long-term ROI in three-phase markets.

In the end, smart buyers don’t compare 7kW and 22kW chargers by price—they compare them by purpose, value, market strategy, and total lifecycle cost.

A thoughtful comparison leads to smarter decisions, stronger margins, and long-term business success.