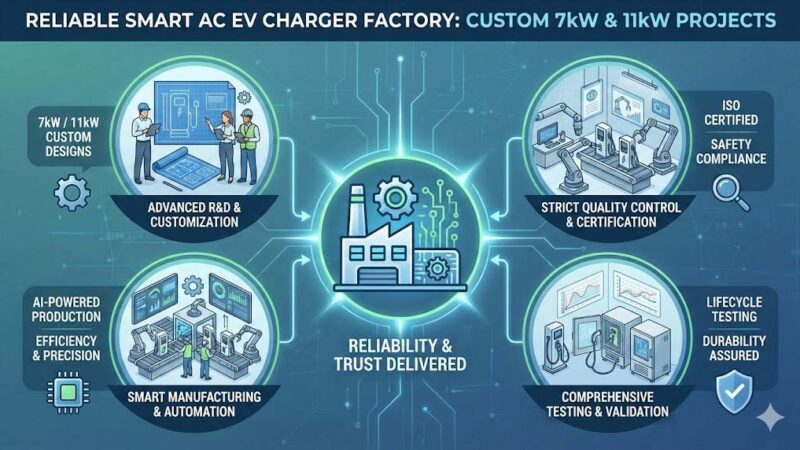

What Makes a Smart AC EV Charger Factory Reliable for Custom 7kW and 11kW Projects?

In the growing world of electric mobility, Smart AC EV Chargers—especially 7kW single-phase and 11kW three-phase models—play a central role in homes, commercial buildings, and public infrastructure across Europe and beyond. Buyers who manage OEM customization, private-label programs, or long-term procurement projects need more than just a competitive price. They need a reliable factory—a partner capable of delivering consistent quality, stable performance, and tailored solutions while supporting them through the entire product lifecycle.

A good EV charger factory is not simply a production line. It is a team of engineers, a commitment to safety, a disciplined workflow, a long-term mindset, and a willingness to stand behind the product even years after deployment. These qualities become even more important when dealing with custom projects, where each buyer may request different branding, enclosures, firmware features, cable lengths, regional requirements, and installation preferences.

This article explores what makes a Smart AC EV Charger factory reliable for custom 7kW and 11kW projects, combining practical factory insight with a human perspective on what buyers truly need.

Table of Contents

1. A Reliable Factory Understands the Real Challenges Buyers Face

Before looking at machinery or certifications, it’s important to understand why reliability matters so deeply to the professionals who purchase chargers.

1.1 Buyers Are Responsible to Their Customers

Procurement managers, distributors, and installers face daily pressure:

meeting project deadlines

avoiding after-sales problems

maintaining reputation

coordinating installation teams

keeping inventory stable

A reliable factory understands these pressures and designs its processes to reduce buyer anxiety, not increase it.

1.2 Custom Projects Add More Complexity

When a buyer requests custom:

branding

cable length

enclosure color

firmware language

RFID behavior

smart-app interface

packaging

the risk of mistakes increases. Only a factory with structured systems can deliver consistent results.

1.3 Long-Term Deployment Requires Predictability

A 7kW home charger project or an 11kW commercial rollout may span months or years. Buyers want a partner who will:

keep models stable over time

support firmware updates

maintain spare parts

avoid unnecessary redesigns

Project stability begins with factory stability.

2. Engineering Strength: The Core of a Reliable Charger Factory

A trustworthy factory starts with solid engineering capability—not just assembly skills, but deep understanding of how AC chargers truly work.

2.1 Engineers Who Understand Real-World European Requirements

Custom 7kW and 11kW chargers must align with:

Type 2 standards

230V single-phase or 400V three-phase grids

DC leakage detection requirements

RCD integration

electromagnetic compatibility rules

Factories with engineers experienced in European markets deliver more reliable products.

2.2 Robust Electrical Architecture

Reliability begins with:

stable PCB layout

optimized heat dissipation

balanced phase loading

accurate current sensors

surge and overvoltage protection

Sloppy electrical design leads to overheating, charging interruptions, relay welding, or communication errors.

2.3 Firmware Expertise for Custom Functions

Smart chargers rely heavily on firmware. A capable factory can customize:

charging current behavior

timing of CP/PP signals

app and cloud interactions

RFID modes

load balancing

dynamic current adjustment

Reliable factories maintain firmware version control and ensure consistency across batches.

2.4 Mechanical Engineering for Daily Use

A charger’s housing must be:

waterproof

UV-resistant

durable against impact

stable under heat load

easy to install

Materials and internal structure matter just as much as electronics.

3. Mature Production Systems Ensure Consistent Quality

A reliable factory doesn’t depend on “good workers”—it depends on good systems.

3.1 Automated SMT Lines for Consistent PCB Quality

Precision pick-and-place machines ensure:

accurate component positioning

low solder defects

stable performance

Smart chargers depend on high-quality PCB assembly.

3.2 Well-Trained Workers for Assembly

Even in automated factories, human skill matters. Reliable manufacturers invest in:

onboarding programs

monthly training

standard operating procedures

safety workshops

quality awareness culture

Workers who understand what they’re building deliver better products.

3.3 Strong Quality Control at Every Stage

Reliable factories use multilayer QC:

IQC (incoming components)

IPQC (during assembly)

FQC (before packaging)

OQC (before shipment)

Each step prevents defects from reaching customers.

3.4 100% Functional Testing of Smart Chargers

Every unit must pass:

full-load charging simulation

CP/PP waveform detection

RCD function validation

overtemperature protection checks

internal communication tests

firmware version verification

This ensures that every charger works the moment it is installed.

4. Ability to Handle Customization Without Losing Quality

Customization is often where unreliable factories fail.

A reliable manufacturer balances flexibility with discipline.

4.1 Custom Branding and Appearance

Factories must handle:

custom logos

custom housing colors

custom LED patterns

custom packaging

region-specific manuals

While ensuring that changes do not impact safety or internal structure.

4.2 Custom Cable Options

Buyers of 7kW and 11kW chargers often request:

different Type 2 cable lengths

different jacket materials

anti-freeze flexible cables for cold countries

custom plug designs

A reliable factory evaluates whether each request affects safety or thermal performance.

4.3 Firmware and App Customization

Customization may include:

new languages

new user flows

personalized error messages

custom current settings

home-energy management integration

Only factories with strong firmware teams can deliver these safely.

4.4 Custom Installation Requirements

Some markets require:

different backplates

angled mounting brackets

customized wall templates

Reliable factories design accessories that align with real installer needs.

5. Long-Term Component Sourcing Stability

Smart charger reliability depends on stable sourcing—not switching parts frequently.

5.1 Long-Term Contracts With Trusted Suppliers

Reliable factories secure stable supply for:

relays

microcontrollers

CT sensors

leakage detection modules

cable materials

This prevents performance drift across batches.

5.2 Component Traceability

A reliable factory maintains:

supplier batches

date codes

testing records

revision logs

If an issue arises, they can trace it back instantly.

5.3 No Sudden Component Substitutions

Sudden changes create:

firmware incompatibility

electrical instability

unexpected thermal behavior

Reliable factories avoid substitutions unless absolutely necessary and always inform buyers early.

6. Clear Communication and Professional Project Management

Even the best product is frustrating if communication is unclear.

6.1 Dedicated Project Managers

A reliable factory assigns managers who:

understand technical requirements

coordinate engineering and production

track deadlines

provide documentation

respond quickly

This reduces misunderstandings.

6.2 Transparent Development Timeline

Buyers appreciate:

honest lead times

clear production stages

predictable release dates

early warnings if delays appear

Transparency is part of reliability.

6.3 Regular Progress Reports

Professional buyers prefer factories that provide:

video updates

production photos

quality inspection reports

test results

sample confirmations

These updates reduce stress during custom projects.

7. Reliability in Certifications and Compliance

A trustworthy factory understands certification deeply—not just as a requirement, but as a responsibility.

7.1 Understanding European Compliance

Relevant areas include:

CE

EMC

LVD

EN 62196

EN 61851

DC leakage detection

smart communication standards

This knowledge protects buyers from legal or regulatory problems.

7.2 Offering Support for Buyer-Specific Certifications

Some custom projects require:

national tests

local lab validation

extended EMC testing

Reliable factories support the process willingly.

7.3 Maintaining Consistent Documentation

Quality factories maintain:

user manuals

wiring diagrams

MSDS files

installation guides

declarations of conformity

Document stability is often overlooked but extremely important.

8. Strong After-Sales and Long-Term Support

A reliable factory stands behind its charger long after production is complete.

8.1 Technical Support Teams

Buyers need help with:

installation questions

firmware behavior

charging compatibility

unusual EV behavior

Support quality matters just as much as product quality.

8.2 Warranty Handling With Respect and Fairness

Trustworthy factories:

replace defective units quickly

diagnose recurring issues

help analyze field feedback

provide engineering solutions

Good after-sales service protects both the buyer and the end user.

8.3 Spare Parts Availability

A stable factory maintains:

replacement PCBs

cables

housings

sensors

relays

firmware files

This ensures long-term operability for custom projects.

9. Commitment to Long-Term Product Stability

Custom buyers depend on the model remaining consistent for years.

9.1 Avoiding Unnecessary Redesigns

Stable factories keep:

enclosure molds

PCB designs

firmware architecture

consistent across production cycles.

9.2 Keeping Firmware Upgradable but Controlled

Reliable manufacturers offer:

OTA updates

controlled versioning

compatibility guarantees

This prevents fragmentation across batches.

9.3 Maintaining Model Longevity

A buyer should never hear:

“We stopped producing this model.”

“We replaced your design with a new one.”

“Parts are no longer available.”

Reliable factories protect custom projects from unexpected discontinuation.

10. A Human-Centered Mindset: The True Foundation of Reliability

Beyond machinery, certifications, or engineering, a reliable factory is guided by human values.

10.1 They Understand Buyer Pressure

Customers rely on buyers.

Buyers rely on factories.

Reliable factories understand this chain and design their processes to prevent stress.

10.2 They Respond Quickly Because They Care

Fast response reflects:

respect

empathy

professionalism

Factories with this mindset build long-term relationships.

10.3 They Treat Product Quality as Personal Pride

At good factories, engineers take pride in:

clean PCB layouts

quiet relays

stable firmware

smooth connector locking

precise testing

Pride creates reliability that cannot be faked.

Conclusion: Reliability Comes From Engineering, Process—and Heart

A Smart AC EV Charger factory is reliable for custom 7kW and 11kW projects when it demonstrates:

strong engineering capability

consistent production processes

disciplined QC systems

stable component sourcing

predictable communication

certification expertise

supportive after-sales service

long-term product commitment

a human mindset focused on trust and partnership

Professional buyers choose reliable factories not because it is convenient, but because their own brand depends on it.

A stable, supportive, technically competent factory becomes more than a supplier—it becomes a growth partner, a trusted ally, and the foundation of every successful EV charging project.